THE SMART WAY TO USE WOOD

Why Kielsteg?

Kielsteg is a series of lightweight, high-performance wooden construction elements used to form roofs and structural floors. Their strength comes from a unique cellular structure in which top and bottom layers of solid wood are linked by vertical webs of plywood or OSB. In cross-section, the webs form a characteristic curve in the form of a boat’s keel; hence the name Kielsteg, meaning ‘keel-web’.

When you build with Kielsteg, you can:

Maximize flexibility

Kielsteg enables architects to design wide column-free spaces, ensuring maximum flexibility of use.

Save material

The ingenious arrangement of the wood in the Kielsteg elements saves weight and ensures unbeatable structural performance.

Increase sustainability

sing the renewable material wood helps protect the climate and fulfil our responsibility to future generations.

STRONG, EFFICIENT, ECONOMICAL

Wide spans

Kielsteg can be used to create roof spans from 6 to 27 m and structural floors with spans of 3 to 13 m. Its load-bearing performance across these wide spans gives designers and users the freedom to do whatever they want with the space.

Kielsteg can be used to form cantilevered projecting roofs up to 10 m deep without any additional reinforcements or supports, creating aesthetically and technically clean and simple solutions.

Kielsteg elements are produced both in a flat version and in a version cambered along their length. The cambered versions extend the range of design load that can be carried within required deflection limits (serviceability).

RAPID, UNCOMPLICATED, EFFICIENT

Promoting efficiency

Kielsteg roof and floor assemblies occupy less built height than many alternative systems. For any given total height of a building, this helps achieve the maximum free height in the interior.

The factory production process with guaranteed parameters and standards ensures constant quality and enables detailed prefabrication for specific projects. In turn, the high level of prefabrication saves construction time on site.

Without any additional treatment, Kielsteg elements achieve a fire resistance of up to REI 60. The space inside the elements can be used to install pipes and wiring.

ECOLOGICAL, SUSTAINABLE, RESOURCE-EFFICIENT

Naturally sustainable

Kielsteg is PEFC-certified. The cellular structure of Kielsteg concentrates the wood exactly where it contributes to the structural performance. This means that Kielsteg contributes to sustainability both by using a renewable raw material (which sequesters CO2) and also by using it very efficiently.

The wide spans that can be achieved with Kielsteg reduce the number of internal supports needed in a building and because this makes the interior more adaptable, Kielsteg can help to make the service life of buildings longer. With their light weight, Kielsteg elements make it easier to add new structures on top of existing buildings and help reduce or eliminate the need to strengthen the substructure. In the same way they help to reduce the load on the foundations of new buildings.

Kielsteg roofs are suitable for use both as platforms for solar panels and also as green roofs.

DISTINCTIVE, PREMIUM, NATURAL

See the quality

The natural, untreated surfaces of Kielsteg have a distinctive striped appearance that designers can use to add a touch of class.

Kielsteg surfaces also add to the look and feel of a space: you can use them to enhance subjective thermal comfort, colour mood and acoustic quality.

No extra cladding of the elements is needed either for aesthetic reasons or for fire resistance. As an unbroken wooden surface, a Kielsteg ceiling can also be used to attach utilities and fittings.

Production

Just-in-time manufacturing

The Kielsteg construction elements are manufactured in Austria by Kulmer Holz-Leimbau GmbH. Kulmer have more than 30 years’ experience in wooden building and have a well-deserved reputation as a pioneer with innovative laminated wood products, which they make in their 14.500-m² factory.

The production line is highly flexible and manufactures all the Kielsteg elements, in heights from 280 to 800 mm and in lengths of up to 35 m, either flat or cambered along their length. All production steps (sorting, finger jointing, planing, glue application, assembly and pressing) are carried out in accordance with the high standards of the structural wood lamination industry and are monitored by the materials testing laboratory at the University of Stuttgart.

NEWS

Keep up to date

Latest news, topics and projects

INTERSPORT Siebzehnrübl: Efficient use of space with KIELSTEG

Intersport Siebzehnrübl, one of the largest sports retailers in south-east Bavaria, is expanding its flagship store in Altötting. The new extension, which will increase the existing sales area to approx. 1,700 square meters, will also be the architectural flagship of

Updated EPD for Kielsteg

In the EPD (Environmental Product Declaration) issued and recalculated on 28.03.2024, we now also make visible the improved energy supply for the production of KIELSTEG timber construction elements through a PV system since 2022. The EPD is certified in accordance

Schweizerhof hotel spa “das Badehaus” – “the bath house“

The Schweizerhof in Flims is a 4-star hotel opened in 1903, now run by the 4th generation of the Schmidt family. In this project, it has expanded its spa facilities in a harmonious fusion of new and old. A new

The Kielsteg roof helps to keep the rooftop extension within its weight target

The headquarters of the pump manufacturer Hidrostal AG

Sports hall Šentilj

Šentilj is a small town in the northeast

KIELSTEG roof on Billa Supermarket in Telfs

BILLA has had a branch in Telfs since

Presentation at the Mass Timber Conference in Portland, Oregon / USA

We are pleased that MINDA Industrieanlagen gave us

KIELSTEG roof on EDEKA store of the future in Nauen

The food retailer EDEKA Minden-Hannover commissioned ZRS Architekten

The Austrian Green Planet Building© Technology Award!

The Austrian Green Planet Building© Technology Award! The

Project portfolio

Buildings

Browse a selection of the most interesting Kielsteg projects in Europe from recent years. Every one of these projects is an example of how to use Kielsteg to realise top-quality solutions to architectural, functional and environmental demands.

By choosing Kielsteg, the owners, architects and engineers demonstrated their understanding of the values of contemporary buildings – using wood as a highly sustainable, but also high-performance construction material.

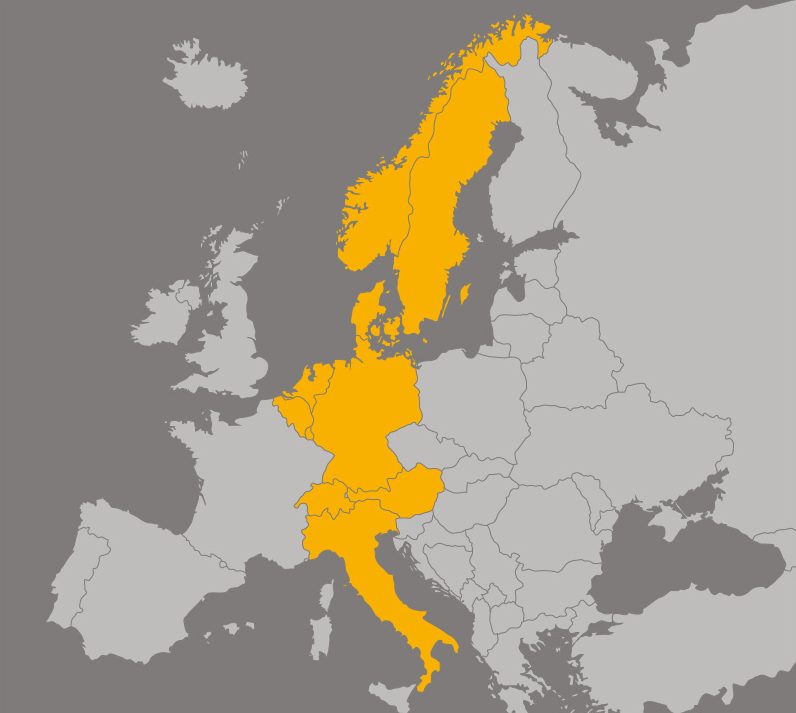

DISTRIBUTORS

Consulting and support throughout Europe

We have highly competent distribution partners in many European countries, who can give you good advice and service. Experienced engineers can answer your questions on structural design, building physics and fire protection. We will help you develop a building concept with the Kielsteg system, and with the dimensioning of the Kielsteg elements.

AUSTRIA

ZMP GmbH

BELGIUM

Laminated timber solutions

GERMANY

KIELSTEG Deutschland GmbH

ITALY

MAK Building GmbH

NORWAY

Wood by Control AS

SWITZERLAND

Holz Stürm AG

CONTACT

Write to us!

Do you have questions about Kielsteg? Should we call you back? How can we help? Fill out the form to send us a message.

Service

Order our sample box!

The box contains a sample of a Kielsteg element and our current project portfolio. On over 100 pages, it contains detailed descriptions of the most interesting buildings that have been made with Kielsteg in recent years in Europe. Simply fill out the order form and we will send you the free sample box.

E-BOOKs

More than 140 pages of Kielsteg projects

The current edition of our project portfolio presents many examples of successful Kielsteg projects, illustrating the wide range of possible applications. Office and commercial buildings, factories and warehouses, supermarkets, R&D institutes, schools, kindergartens, restaurants, shops, and adding extra storeys to existing buildings all feature.

Technical handbook for architects and engineers

The 132-page technical handbook is an essential guide to using Kielsteg elements, covering design, structural engineering, detailing and building physics. The spectrum of possible Kielsteg applications is explained with a repertoire of practical project examples. A comprehensive introduction and reference for architects, designers and engineers.

WHAT PEOPLE SAY

Motivation and ambition

APPROVALS AND CERTIFICATES

Innovation in wood

The European Technical Assessment regulates the manufacturing and use of KIELSTEG elements in the member states of the European Union as the basis for the CE certification mark.

Environmental Product Declarations (EPD) provide the data for environmental assessments. They enable meaningful comparisons of building materials for the first time. A cradle-to-grave EPD enables comparisons in systems or in whole buildings, over their whole life cycle.

PEFC, the Program for the Endorsement of Forest Certification Schemes, is a certification and labelling program for products derived from ecologically, economically and socially sustainable forestry – covering the entire processing chain. When customers buy products with the PEFC label, they can be sure that their purchase supports environmentally friendly forestry.